Work Hours

Mon ~ Fri: 10:30 am - 6:30 pm

Sat: 10:30 am - 3:00 pm

Sundays, Holidays (Closed)

Radical Gear

for the Detail-Obsessed

Unique PD Ecosystem

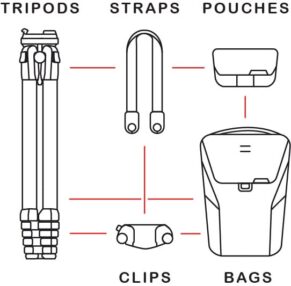

The future of how we utilize our stuffs is here. Peak Design brings together a collection of award-winning photo gears, straps, bags, organizers and tripods into an amazing ecosystem that allows all these to integrate, interoperate and function seamlessly together to create the most amazing user-experience.

Peak Design Mobile

Meet the most brilliant phone mounts and accessories on the planet!

Effortless one-handed attachment and removal. High-strength and precision-tuned magnets for the rigors of everyday carry. Mechanically locking mounts machined out of aluminum for extreme activities. And at the center, a beautiful, slim and protective phone case.

Repository of stories, reviews, and insights from our in-house writers and friends on everything about creativity, gear and travel.

Repository of tips, product information, and resources that will enable you to best use, and maximize the products you purchase from us.

Join the mailing list, and always be on top of the latest news, special privileges, exciting deals, vouchers and irresistible discounts!